Green Nitric Acid New Project, Leading Low-Carbon Transformation

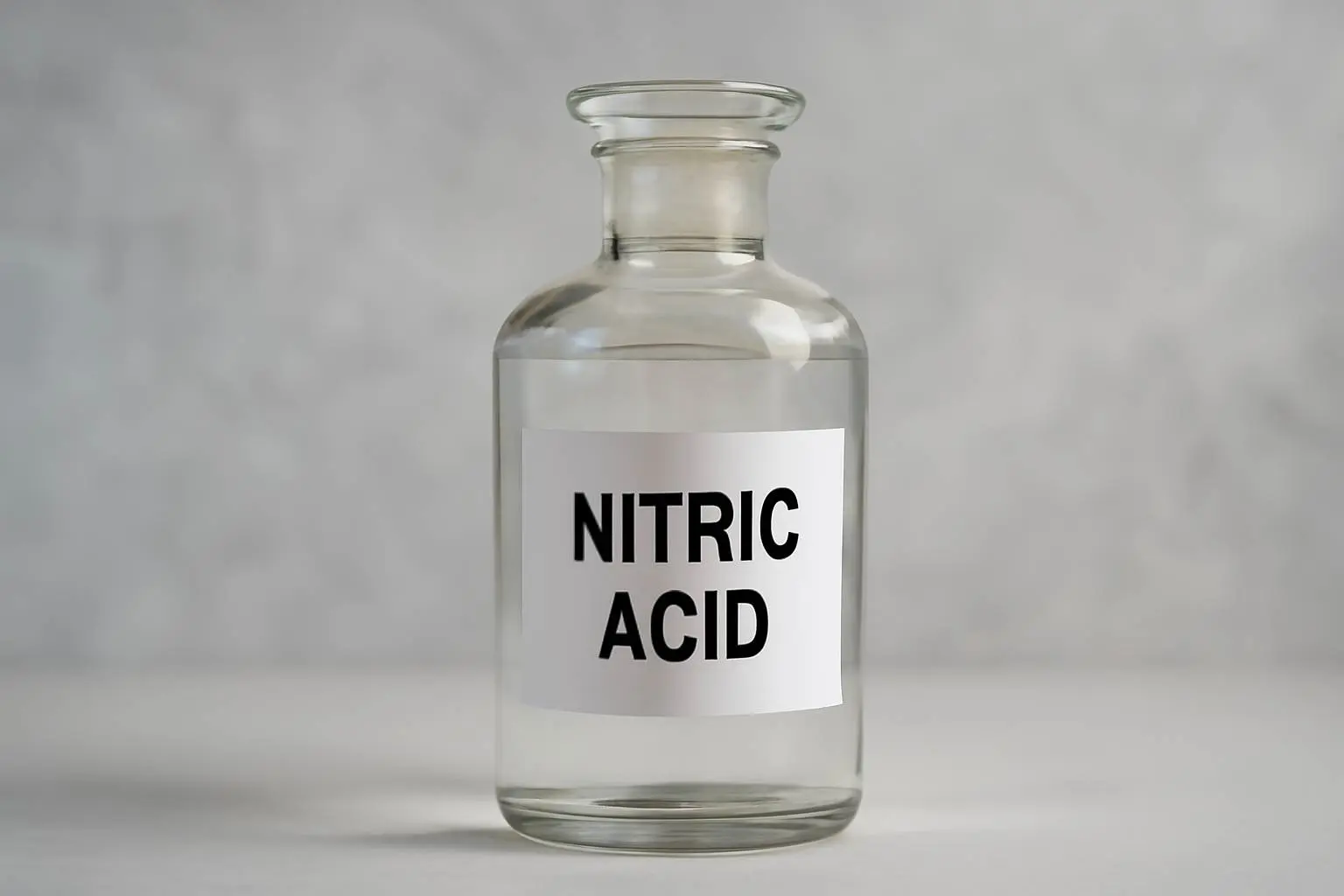

In response to China's "Dual Carbon" strategic goals and to strengthen its leading position in the nitric acid industry, Henan Yongchang Nitro Fertilizer Co., Ltd. has been starting a new plant with the "Dual-Pressure Low-Temperature Plasma Coupling Process" at its existing 500,000-ton nitric acid production base.

This expansion will add 100,000 tons of high-purity nitric acid capacity. The project adopts the world's first near-zero nitrogen oxide (NOx) emission technology, marking a new era of green intelligent manufacturing for China's nitric acid industry:

1. Technological Breakthrough: Decoding the Fourth-Generation Nitric Acid Production Process

● Energy Consumption Revolution: A four-stage reaction pressure cascade utilization system reduces steam consumption, lowering comprehensive energy use.

● Purity leap: Using plasma activation technology, the product concentration has broken through the technical bottleneck of 68% and can be directly used for electronic grade nitric acid production

● Environmental Protection: Integration of non-precious metal catalysts and membrane separation systems cuts exhaust NOx emissions, stricter than national standards.

2. Market Strategy: Strengthening Top-Three Industry Positioning

● Capacity Leap: Total annual capacity will reach 600,000 tons

● Product Upgrade: electronic grade nitric acid production line introduced to enter high-end fields such as semiconductor cleaning.

● This expansion is not only about adding production capacity, but also about climbing the value chain from basic chemicals to fine chemicals.

3. Green benefits: the first move in the era of carbon tariffs

● Resource regeneration: Absorption tower waste heat power generation meets 30% of the device's electricity demand;

● ESG Value: As a Clean Production Leader in the Nitrogen Fertilizer Industry, easier to receive preferential green credit at lower interest rates.

Industry experts believe that this is a model of upgrading traditional chemical industry, transforming basic chemical manufacturing into a technology intensive industry through process innovation, and exploring a feasible path for the nitric acid industry to 'reduce carbon emissions without reducing production'.