How Concentrated Nitric Acid Shapes the Future of Industrial Efficiency

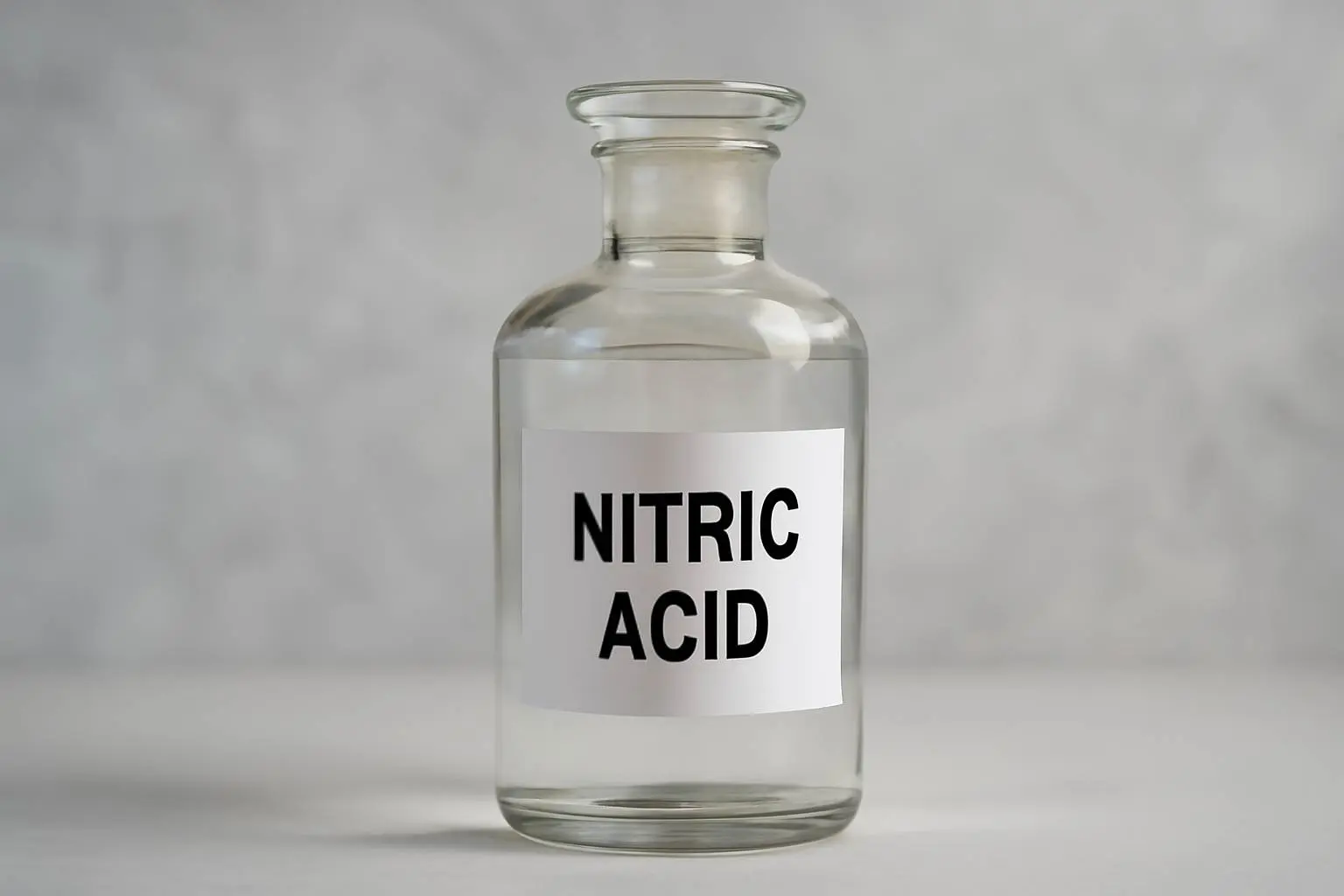

You see concentrated nitric acid shape modern industry in many ways. Its high reactivity and purity help you achieve faster, more controlled results.

- The Concentrated Nitric Acid market reached USD 25.19 billion in 2021.

- It is projected to grow to USD 33.43 billion by 2029.

| Efficiency Driver | Impact |

|---|---|

| Technological Advancements | You unlock new efficiency benchmarks with innovative collaborations. |

| Digital Integration | You optimize reactor performance and reduce downtime. |

| Regulatory Compliance | You align investments with sustainability goals. |

Concentrated Nitric Acid: Properties and Efficiency Drivers

Molecular Structure and Reactivity

You can understand the power of concentrated nitric acid by looking at its molecular structure. This acid, known as HNO₃, has a unique arrangement of atoms.

- The molecule shows two main resonance forms.

- The N–O bonds are almost equal in length and shorter than a normal single bond. This means the bonds act like they have some double bond strength.

- Because of this structure, concentrated nitric acid can form the nitronium ion (NO₂⁺). This ion reacts quickly with other chemicals.

This special structure lets you use concentrated nitric acid in many fast and controlled reactions. You can count on it to help you make products more efficiently

Oxidizing Power and Industrial Purity

You rely on concentrated nitric acid for its strong oxidizing power. This means it can help break down or change other substances quickly.

- You use hot and concentrated nitric acid as a main oxidant to break down organic matter.

- You find it in nuclear fuel reprocessing, where it helps form nitrate complexes with uranium and plutonium.

- In copper chemical mechanical polishing (CMP), you use nitric acid to help form Cu(II) ions.

- You also use it in analytical geochemistry to decompose organic matter.

| Study Description | Findings |

|---|---|

| Potentiodynamic studies on copper | Nitric acid oxidizes copper without passivation, causing copper to dissolve and the surface to become rougher. |

You see that concentrated nitric acid works well in many industries because it keeps its strength and purity.

- High-purity grades are important in electronics and pharmaceuticals. Impurities can lower product quality and reliability.

- Using pure nitric acid helps you keep your workplace safer and meet environmental rules.

- You need high-purity acid for strict quality control in semiconductor factories.

Tip: When you choose high-purity concentrated nitric acid, you improve both your product quality and your process safety.

Concentration Levels and Their Industrial Impact

You can adjust the concentration of nitric acid to fit your needs. Higher concentrations give you stronger reactions and faster results. Lower concentrations work better for gentle or controlled processes.

- In fertilizer production, you use high concentrations to make Ammonium Nitrate quickly.

- In metal processing, you pick the right concentration to clean or etch metals without damaging them.

- In electronics, you need very pure and sometimes less concentrated acid to avoid harming delicate parts.

You see that by choosing the right concentration, you can save time, reduce waste, and get better results in your industry.

Concentrated Nitric Acid in Key Industrial Applications

Fertilizer and Ammonium Nitrate Production

You play a key role in feeding the world when you use concentrated nitric acid in fertilizer production. This acid helps you make important fertilizers like ammonium nitrate, Ammonium Phosphate, and potassium nitrate. These fertilizers help crops grow faster and stronger. You can see how each application uses concentrated nitric acid in the table below:

| Application Type | Description |

|---|---|

| Ammonium Nitrate | Core component in its production |

| Ammonium Phosphate | Essential for its manufacturing |

| Potassium Nitrate | Integral in the production process |

You improve efficiency and output by using concentrated nitric acid. You get faster reactions and higher yields, which means you can produce more fertilizer in less time. This helps you meet the growing demand for food around the world.

Explosives and Specialty Chemicals Manufacturing

You rely on concentrated nitric acid to make explosives and specialty chemicals. This acid is a main ingredient in the production of ammonium nitrate, which is used in many types of explosives. The defense sector needs more explosives every year, and this increases the demand for high-purity nitric acid. In 2023, defense spending went over $2.2 trillion. This growth means you must use more concentrated nitric acid, which can raise production costs. You also need to follow strict safety rules when handling this powerful acid. By using concentrated nitric acid, you can make explosives that are more reliable and effective.

Note: You must always follow safety guidelines when working with concentrated nitric acid in explosives manufacturing.

Metal Processing and Refining

You use concentrated nitric acid to refine metals and improve their quality. For example, you can purify metallurgical grade silicon by removing impurities like iron, aluminum, and titanium. When you use this acid, you can increase silicon purity from 99.74% to 99.99%. You also achieve extraction efficiencies of over 99% for these metals. This means you get higher quality silicon for use in electronics and solar panels.

You also help reduce waste and recover valuable resources. The table below shows how concentrated nitric acid supports waste reduction and resource recovery:

| Evidence | Description |

|---|---|

| Leaching Agent | You extract valuable metals from low-grade waste, such as scrap TV boards. |

| Selective Extraction | You recover metals like copper and silver while making hazardous waste safer. |

| Regeneration | You can regenerate nitric acid from its reaction products, making your process more sustainable. |

You make your metal refining process more efficient and environmentally friendly by using concentrated nitric acid.

Pharmaceuticals, Dyes, and Pigments

You depend on concentrated nitric acid to make medicines, dyes, and pigments. The demand for this acid keeps growing in these industries. Here are some ways you use it:

- You use it to synthesize active pharmaceutical ingredients (APIs) and drug intermediates.

- You support the production of essential medications.

- You use it in the nitration process to make dyes, colorants, and pigments for textiles, inks, and coatings.

You also need high-purity compounds in these sectors. The table below shows how you use concentrated nitric acid in different fields:

| Sector | Application |

|---|---|

| Chemistry | You use it as a reagent for nitration and to make organic and inorganic compounds. |

| Medicine | You use it to produce pharmaceuticals and APIs. |

| Industry | You need it for making fertilizers, explosives, dyes, and pigments. |

You improve product quality and meet strict industry standards by choosing the right grade of concentrated nitric acid.

Semiconductor and Power Generation Sectors

You use concentrated nitric acid in the semiconductor industry to clean and etch silicon wafers. Its strong oxidizing power helps you remove impurities and keep surfaces clean. This is important for making high-quality computer chips and electronic devices. You need electronic grade nitric acid with a purity of 99.999% or higher to avoid contamination.

- You use it for cleaning and etching processes in semiconductor production.

- You improve process control and increase yield by using high-purity acid.

- You meet the growing demand for semiconductors by adopting concentrated nitric acid in your manufacturing lines.

In the power generation sector, you use concentrated nitric acid to help maintain equipment and improve efficiency. You keep your systems running smoothly and reduce downtime.

Tip: Always use the correct grade of concentrated nitric acid for your application to get the best results and protect your equipment.

You see concentrated nitric acid drive industrial progress, but you also face challenges. Safety innovations like automation lower risks and costs. Environmental rules and raw material prices affect your operations. Leading companies expand production to stay ahead.

| Challenge | Impact |

|---|---|

| Safety & Environment | High risks and strict regulations |

| Supply Chain | Price and availability changes |

| Costs | Fluctuating ammonia and compliance expenses |

By using new technologies and green practices, you help shape a safer, more efficient future for industry.

FAQ

What safety steps should you follow when handling concentrated nitric acid?

You should always wear gloves, goggles, and a lab coat. Work in a well-ventilated area. Store the acid in a safe, labeled container.

Why do you need high-purity nitric acid in electronics?

You need high-purity nitric acid to prevent contamination. Clean acid helps you make reliable computer chips and keeps your products safe.

Can you recycle nitric acid after use in industry?

Yes, you can recycle nitric acid using special equipment. Recycling helps you save money and reduce waste in your factory.